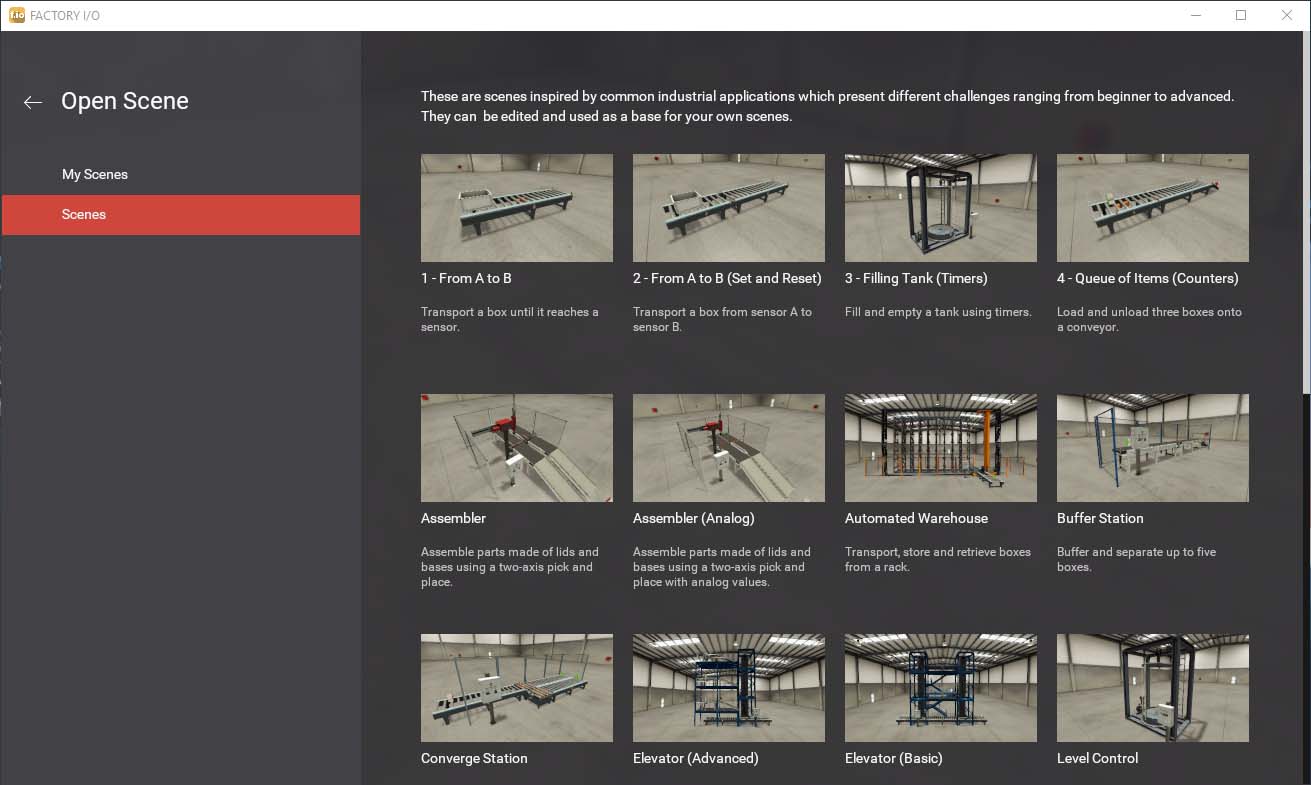

One license includes more than 20 ready-to-use industrial applications.

Factory I/O is a revolutionary 3D factory simulation software developed for industrial automation training (PLC training). It allows the simulation of devices called PLC (Programmable Logic Controller), which are used in the control of functions such as control of production lines or machines in factories, using only one computer.

Factory I/O has been designed with a user-friendly interface and equally easy to use. It helps to quickly and easily create a virtual factory by leveraging a range of common industrial parts.

However, it can also be used with microcontrollers, SoftPLC and Modbus, among many other technologies.

Kliksoft is the authorized reseller of Real Games, which has been working on simulation software for more than ten years.

Kliksoft sells Factory I/O, one of the company’s locomotive products, to academic and public institutions, and private sector organizations.

FACTORY I/O FEATURES

20+ ready-to-use scenes

Factory I/O offers more than 20 scenes inspired by typical industrial applications to practice real world control tasks. Use a scene as it is or as a starting point for a new project.

Library of industrial parts

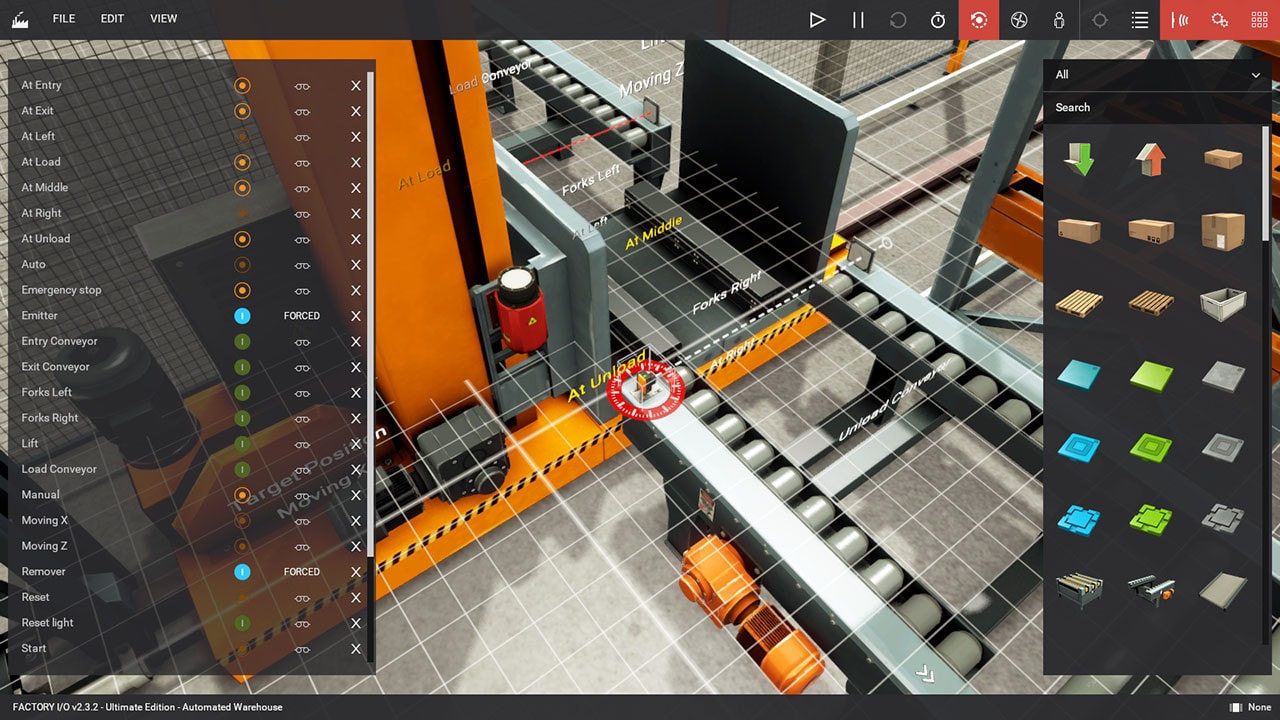

Create a virtual factory using a library of industrial parts, including sensors, conveyors, elevators, stations, and many others.

Kişisel Senaryo Oluşturma

Factory I/O smart editing tools make building a 3D scene a comfortable and natural experience. Use a library of industrial parts and customize Factory I/O by creating your own training scenarios.

Build your own scenarios

Factory I/O smart editing tools make building a 3D scene a comfortable and natural experience. Use a library of industrial parts and customize Factory I/O by creating your own training scenarios.

Digital & analog I/O

Most parts include digital and analog I/O. For example, use a digital value to start or stop a conveyor or an analog value to weigh items or control liquid levels.

Troubleshooting

Practice troubleshooting routines by easily injecting Always On and Always Off failures in sensors and actuators.

Instructor mode

Lock several options with an instructor password. Challenge trainees to complete partially built systems, find malfunctions and failures.

Easy integration

Easily integrate Factory I/O with existent training equipment. Plug and Play with Siemens and Allen-Bradley PLC (Ethernet). May require wiring for other brands through interface boards.